Workshop Creation

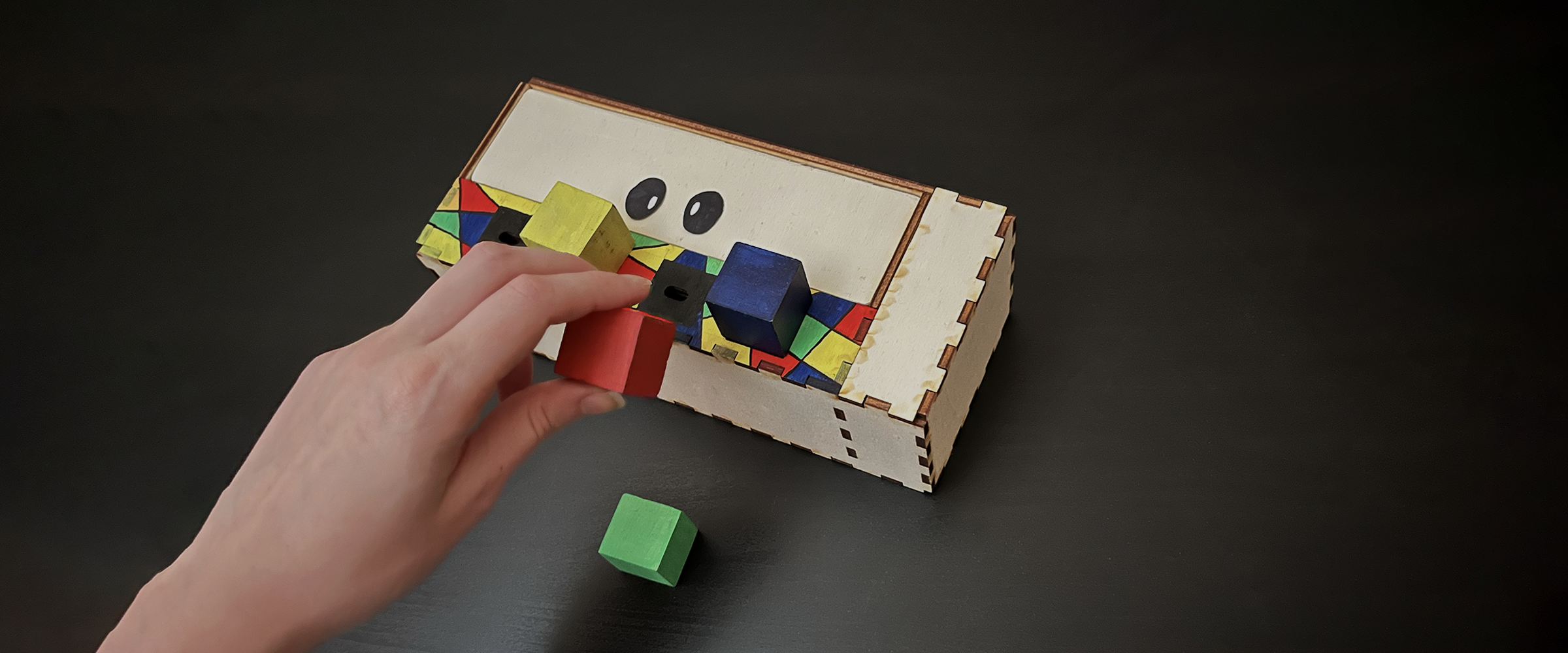

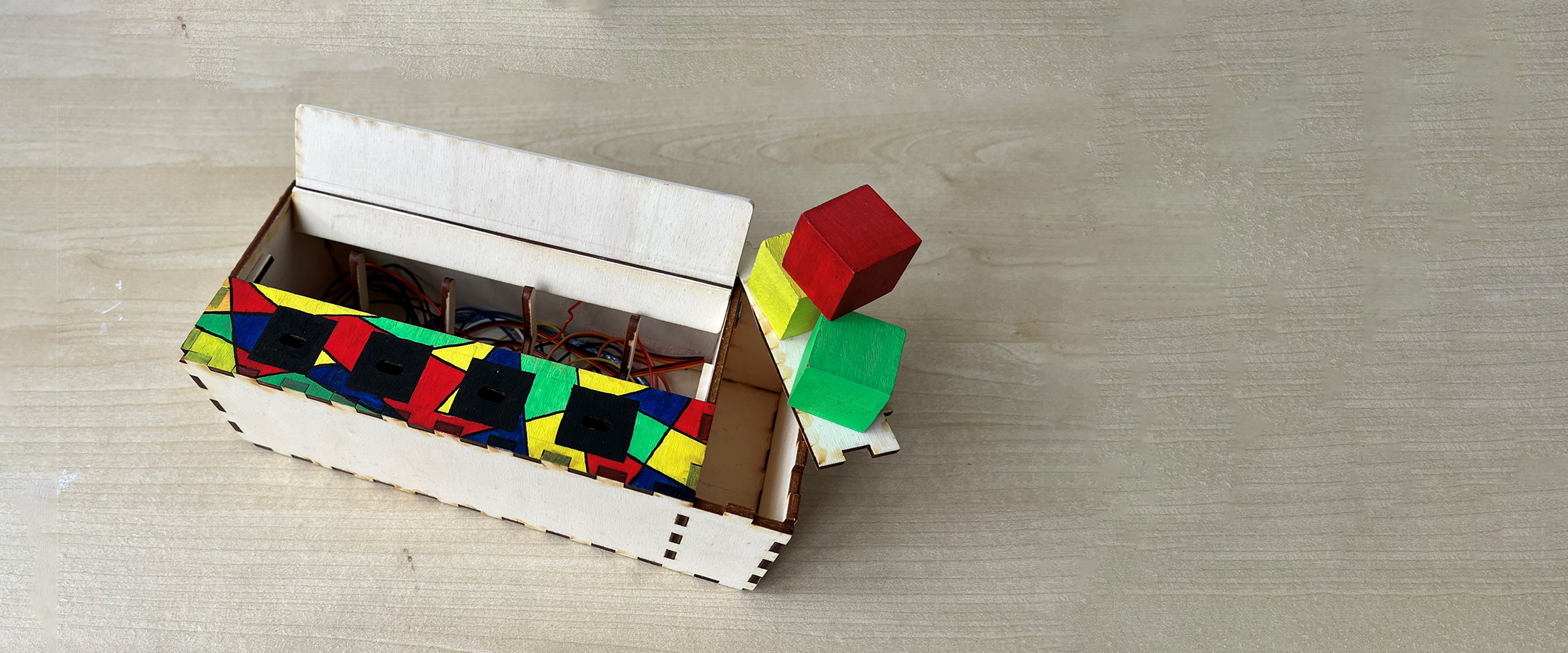

Multiple cardboard prototypes were built to refine the overall structure and shape of the box. The plywood pieces were then laser cutted, polished and assembled.

Electronics

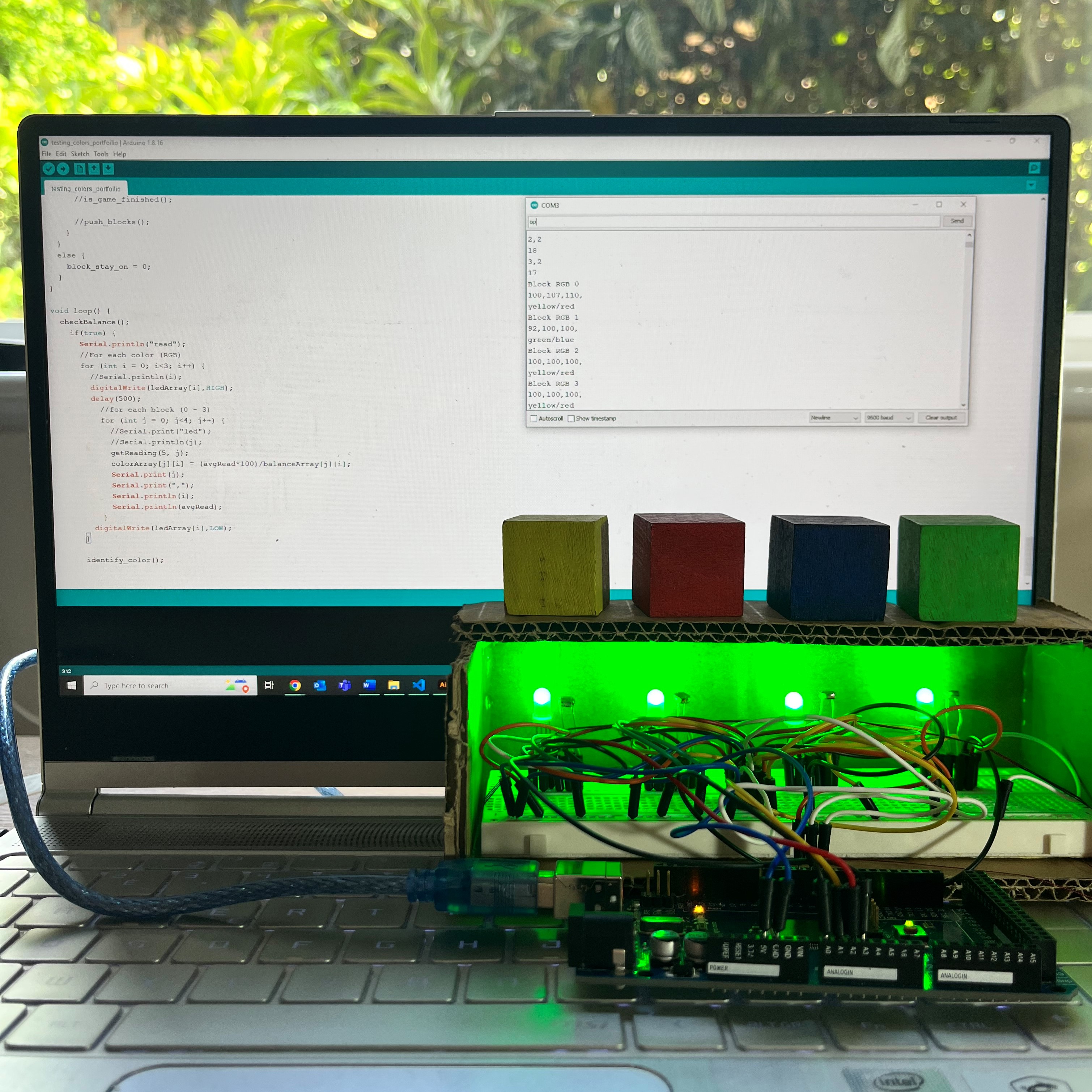

I developed cheap color sensors using RGB LEDs and CDS Photocells, calibrating them to each color. Each arm was individually motorized with a servo motor and controlled with an Arduino Mega 2650.

Programming

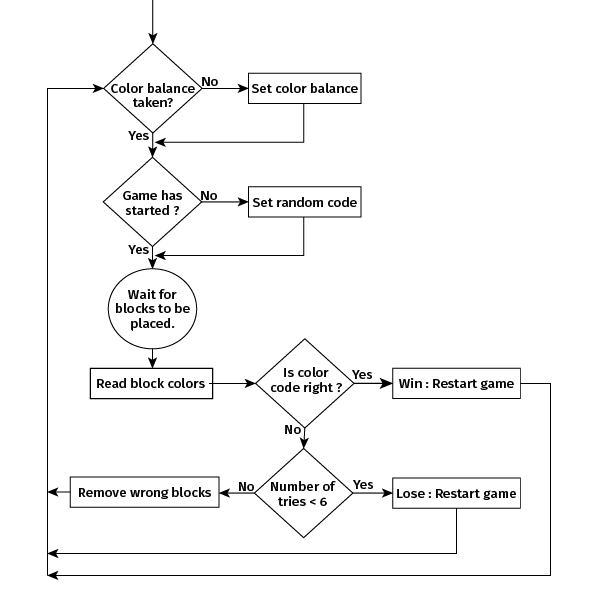

The Color Master was programmed in C++, and taught a variation of behaviors to grant it a ‘sassy’ personality, similar to the reactions a real opponent would have.

Detecting block colors. Without read-made color sensors.

These color sensors were developed with an RGB LED and a CDS Photocell. Red, green and blue is flashed by the LED, and the corresponding reflected light perceived by the CDs Photocells is recorded. The difference in values, identified through a prior analysis, enables each color to be identified.

Programming it's behavior. Sassy like a real opponent.

Robots lack the spontaneity and personality a human opponent would have. Therefore, a series of different movements were taught to the box and selected at random when blocks had to be pushed off.

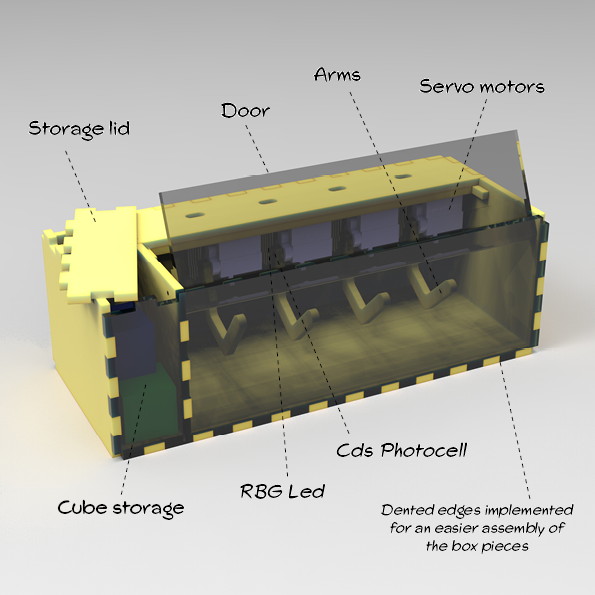

Validating design in CAD. To avoid preventable errors.

Prior to building the Color Master in plywood, a CAD model was created using Solidworks to ensure all components would fit together correctly. The edges of each piece was dented to enable an easier and more precise assembly.