User Collaboration

I conducted extensive surveys and multiple interviews with up to 10 users, collecting essential insights. A closer collaboration with a select few throughout the design process ensured effective validation of our product.

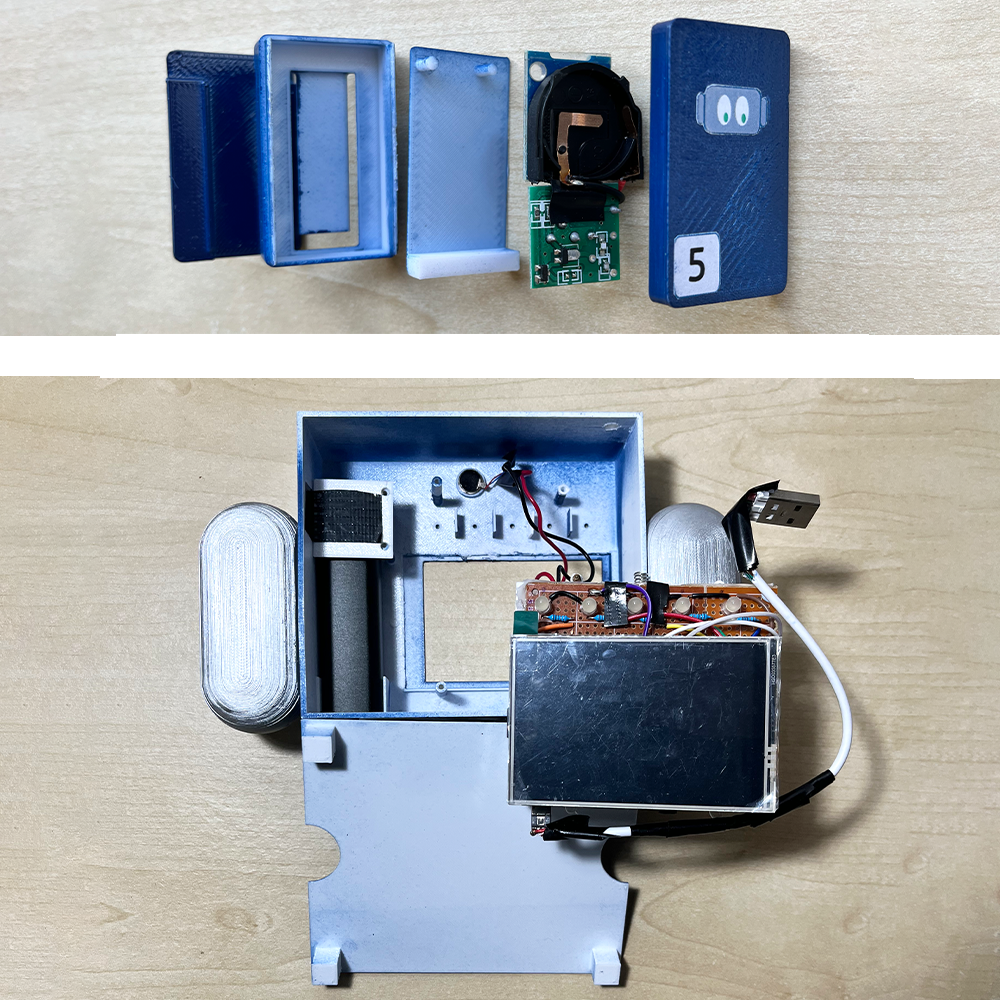

Electronics

I performed thorough desk research about each hardware element to make informed decisions and assembled and soldered the totality of the device and tag’s electronics.

Programming

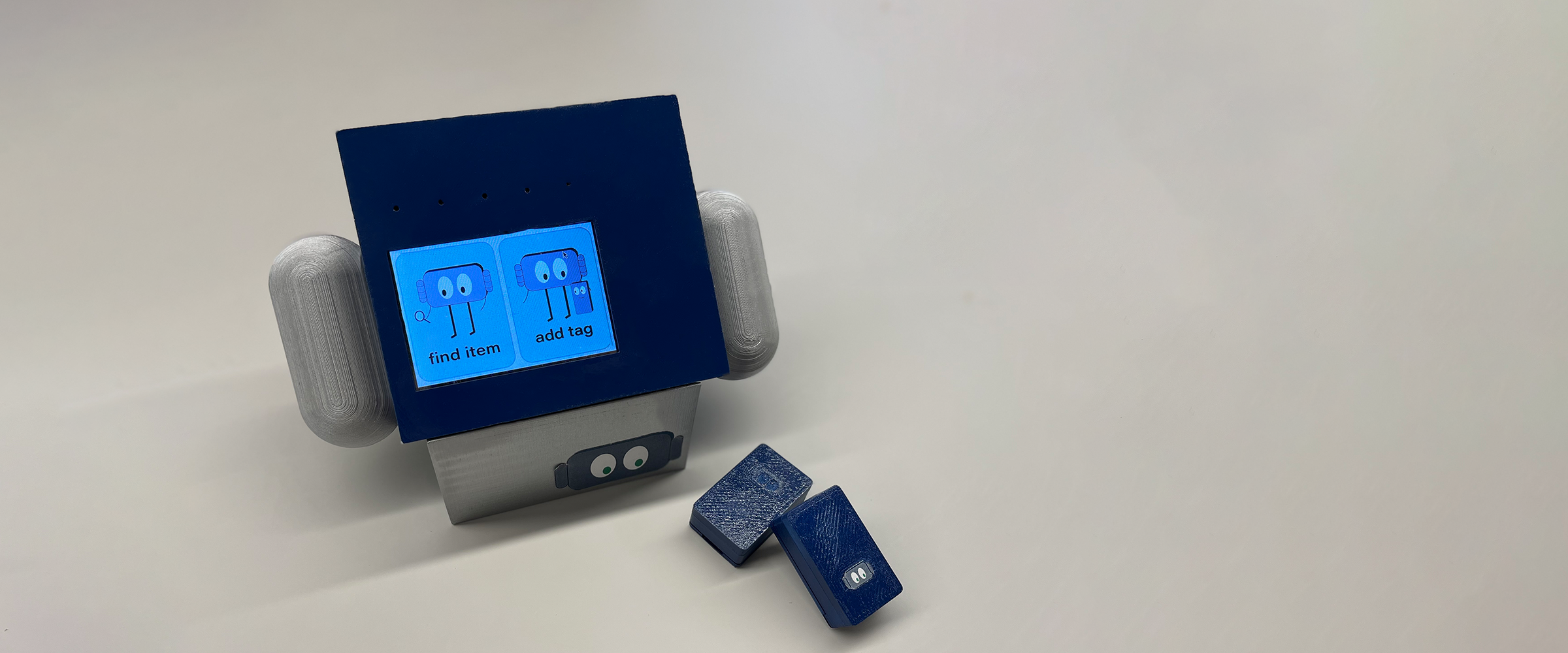

I developed an effective desktop app in Python with PyQt 5, combining control of the screen, vibration, LEDs and RF communication. The tags were programmed with C++ to send reliable messages.

Insightful User Research. Designing a solution made for them.

Multiple online interviews were conducted with senior care-givers to understand which items are frequently misplaced and how this occurs. Additionally, we organized a documented experience with an existing item tracking device over the course of a week with a couple users. The care-givers were quite interested by this concept despite several flaws in the product, such as cost and user experience, which helped us refine our requirements to design our improved solution.

Wireless communication throughout the house. Using Radio Frequency.

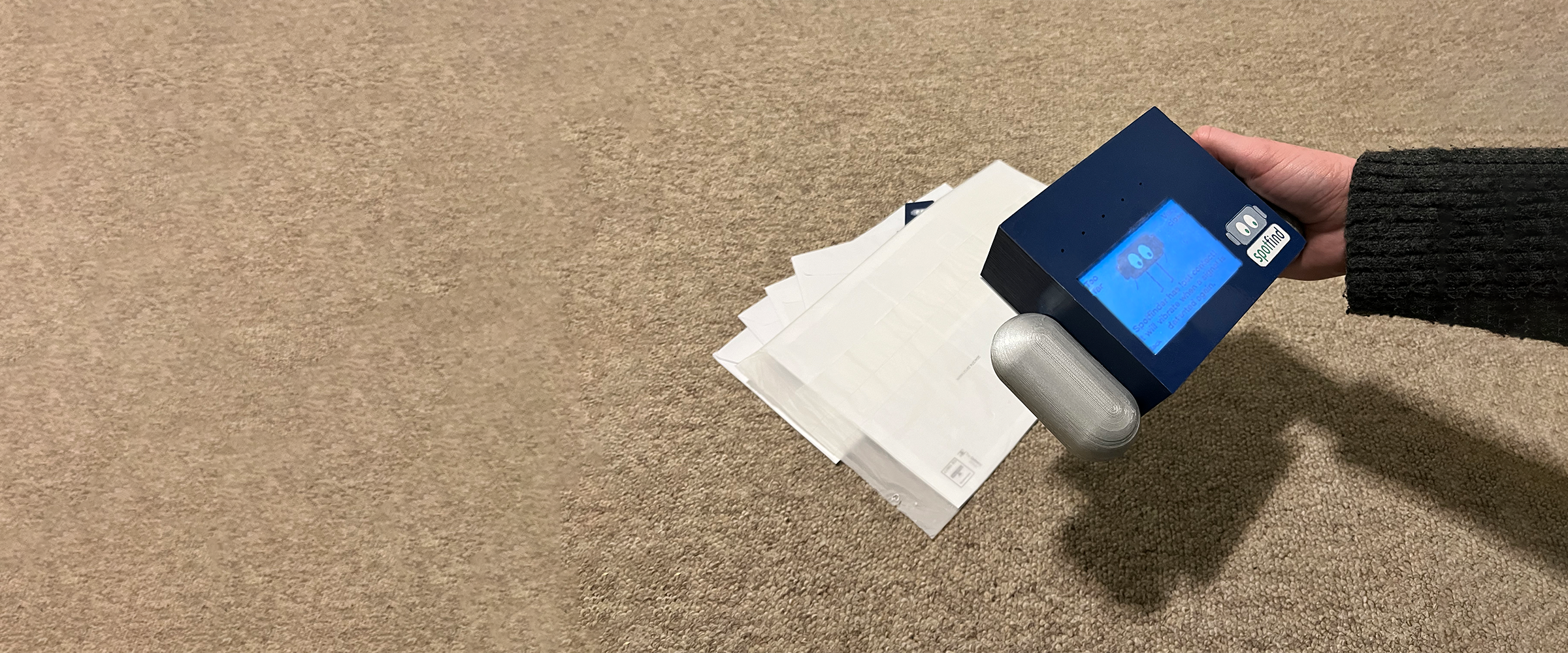

As the CTO of my group, I conducted extensive desk research to analyse all the possible technologies available to measure distance between two systems and decided to use Radio Frequency (RF) as it offered the optimal price to range ratio. Tags were programmed to emit regular messages receivable by the device, enabling it to guide the user towards the item the tag is attached to. The device can linked to a total of 100 tags, which can be stored in the drawer of the main device’s dock.

A Tailored User Experience. Simple and efficient.

Most item trackers on the market are either quite expensive, or unsuited to the elderly with a declining health. We aimed to make the process quick and intuitive, suited to a care-giver’s busy routine. On the main device’s touchscreen, the users can manage all the tags and launch the search. Contrary to most cheap item trackers, the main device leads the users with haptic feedback and LED range rather than having tags attract the users towards them.

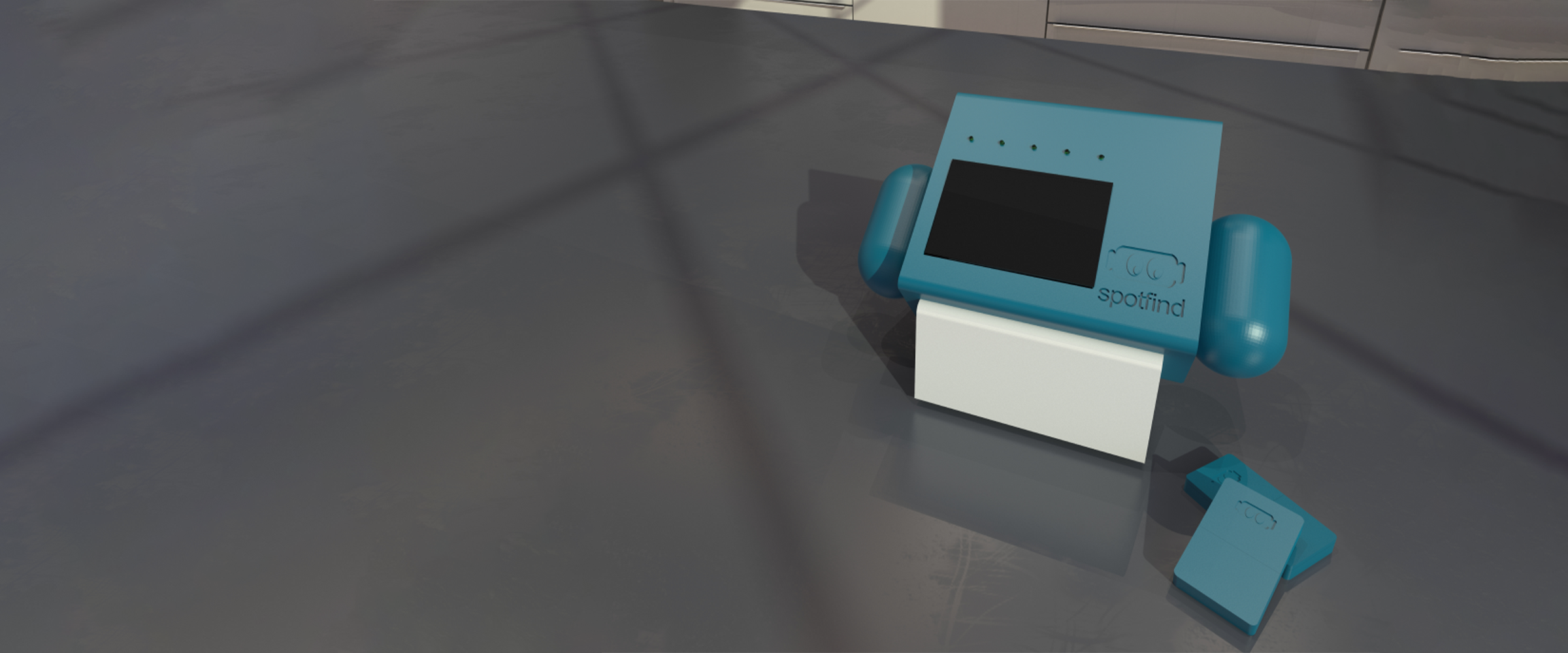

Industry Manufacturing. Designing for a quick and precise assembly.

If this product were to be commercialized, all elements of the casing would be produced with injection molding. The pieces for this prototype were 3D printed, therefore, some aspects of the casing were modified. Self-tapering screw holes and precise positioning support were implemented to ease the assembly process of both devices. The number of pieces was optimized to simplify overall handling and assembly speed.